Labels

Lexicraft Ltd offer single source solutions. Branding (logos), Instructions and Serial numbers are screen or digitally printed on flexible or rigid material. Pressure sensitive adhesives are specified to ensure permanent fixing on the customer product housing or case assembly. For rigid materials mechanical fixings can be specified. PVC, Polycarbonate or Polyester labels are specified to ensure compatibility with the customer operating environment and aesthetic requirements. For aggressive operating conditions images/logos can be sub-surface printed on clear material wherein the substrate provides a protective layer. Alternatively a clear over laminate can be applied.

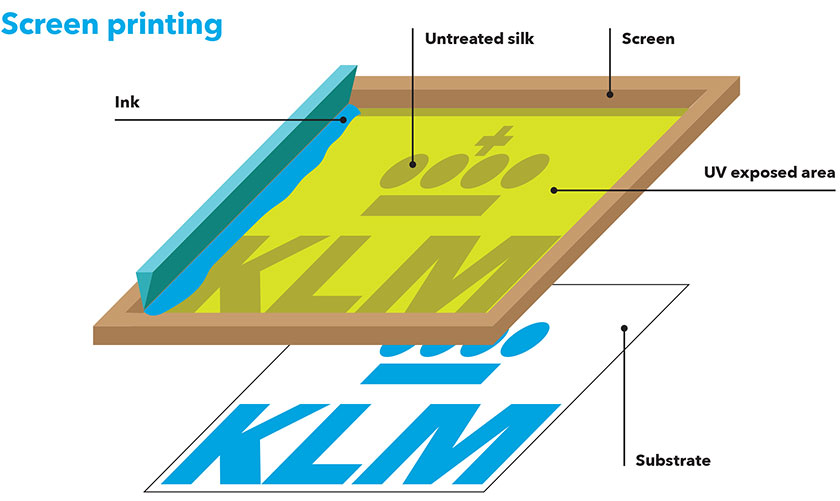

The choice between Screen & Digital printing is very complex and based on a multitude of variables including: – Substrate (vinyl, polyester & polycarbonate), Inks, Colours, Size and Quantity required. Screen printing offers very fine definition and can be more cost effective on larger print runs.

The process of Screen printing is a technique whereby a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed.

Digital printing refers to methods of printing from a digital based image and can be via a laser or inkjet printer. Digital printing has a higher cost per page than more traditional screen printing but the cost is usually offset by avoiding the cost of all the technical steps required to make screens for printing. Other benefits of digital printing can often be the size of the image.